Stainless Steel Filter for Cooling Water Treatment

Stainless Steel Filter for Cooling Water Treatment

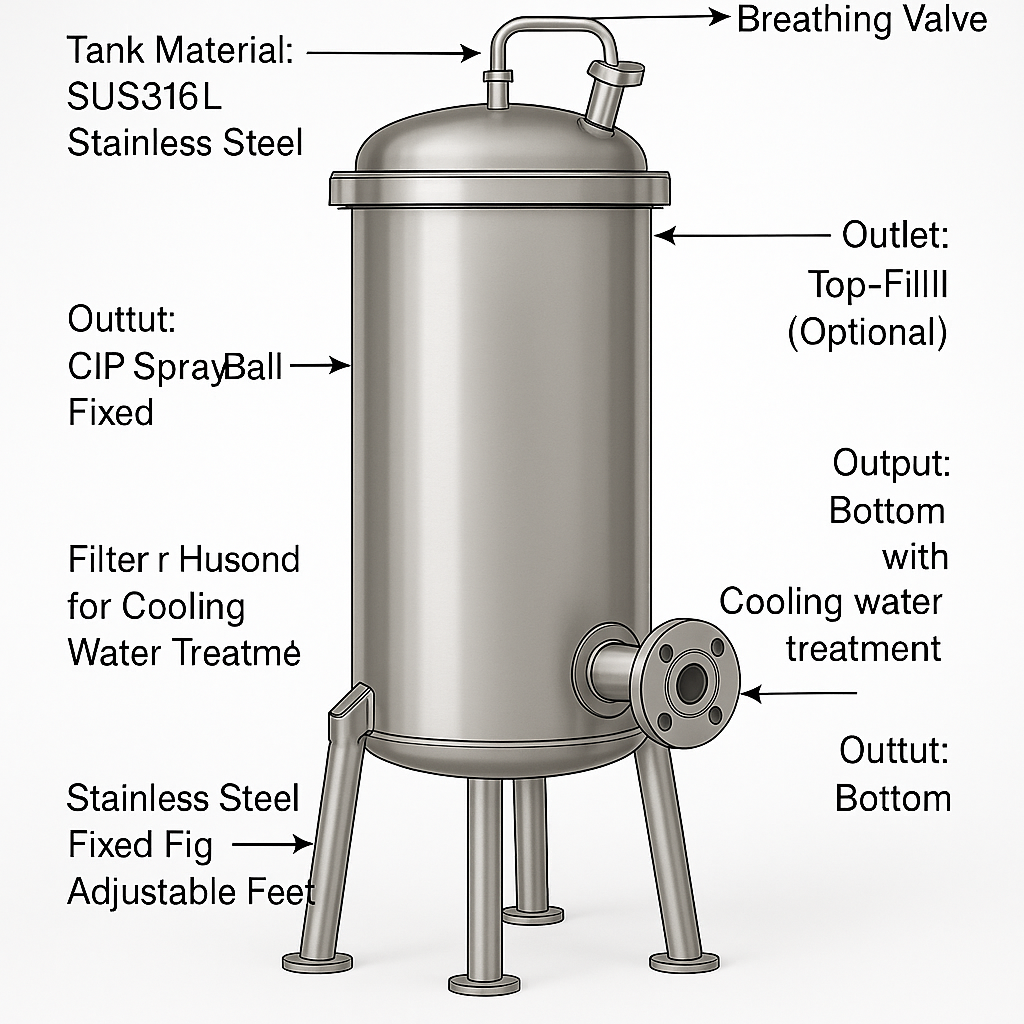

Engineered for durability and performance, STARK’s stainless steel filters are purpose-built for industrial cooling water treatment systems. With customizable configurations—including cartridge, bag, and inline types—these filters ensure efficient removal of particulates, sediment, and suspended solids to protect downstream equipment and maintain water quality standards. Available in SUS304, SUS316, or duplex stainless steel, our filters are fully adaptable to harsh cooling environments and varying flow conditions.

Engineered for durability and performance, STARK’s stainless steel filters are purpose-built for industrial cooling water treatment systems. With customizable configurations—including cartridge, bag, and inline types—these filters ensure efficient removal of particulates, sediment, and suspended solids to protect downstream equipment and maintain water quality standards. Available in SUS304, SUS316, or duplex stainless steel, our filters are fully adaptable to harsh cooling environments and varying flow conditions.

STARK stainless steel filters are designed to meet the operational demands of modern cooling water systems in industrial facilities, HVAC plants, power stations, and chemical processing environments. These filters efficiently remove suspended solids, sand, rust particles, and biofouling materials from recirculating or makeup water, ensuring optimal system efficiency and extending equipment lifespan.

Constructed from high-grade stainless steel (SUS304, SUS316L, or duplex), the filter housing provides excellent corrosion resistance against chemically treated cooling water and varying pH levels. Interior surfaces are mechanically polished or electropolished to minimize scaling and fouling accumulation.

Filter Design Options

We offer multiple filtration formats to meet specific flow, pressure, and footprint constraints:

- Cartridge-Type Filter: Ideal for fine filtration (1–100 micron); easily replaceable elements; suitable for precision protection of heat exchangers or chillers.

- Basket-Type Filter: Designed for coarse filtration (100–800 micron); reusable stainless steel basket insert; optimized for high-flow cooling loops.

- Y-Strainer and Inline Filters: Compact solution for point-of-use protection or system branch lines; available with magnetic rods for metal particle removal.

Customizable Parameters

Each filter can be tailored to specific process conditions, including:

- Connection size and type (DN25–DN300; flanged, threaded, or clamped)

- Flow rate (from 5 m³/h to 200 m³/h)

- Working pressure (standard 1.0 MPa; optional up to 1.6 MPa)

- Housing material (SUS304 / SUS316L / Duplex / lined carbon steel)

- Element type (stainless steel mesh, pleated cartridges, or wedge wire)

Optional features include differential pressure gauges, automatic flushing ports, drain valves, and lifting lugs for large-diameter housings. Units can be integrated into skid-mounted cooling water treatment packages or supplied as standalone inline components.

Whether for central cooling towers or local process chillers, STARK stainless steel filters offer reliable, long-life protection with minimal maintenance and maximum adaptability.

| Parameter | Specification |

|---|---|

| Housing Material | SUS304 / SUS316L / Duplex Stainless Steel (optional lined steel) |

| Filter Element | Stainless steel mesh, pleated cartridge, wedge wire, or multi-bag type |

| Micron Rating | 1μm – 800μm (customizable by application) |

| Working Pressure | Up to 1.0 MPa (1.6 MPa available upon request) |

| Operating Temperature | 5°C to 120°C (dependent on gasket type) |

| Flow Rate Range | 5 m³/h – 200 m³/h per unit (scalable) |

| Connection Type | Flanged (DIN/ANSI), Threaded (BSP/NPT), or Sanitary Clamp |

| Installation Orientation | Vertical (standard), Horizontal (optional) |

| Standard Features | Drain valve, pressure gauge ports, lifting lugs |

| Optional Features | Auto-flushing port, DP sensor, magnetic trap, insulation layer |

| Compliance | GB/T, ISO 9001; welding and pressure test certificates available |

Note: Specifications are fully customizable. For large-volume cooling water projects or OEM system integration, please contact us for detailed drawings and flow selection support.

STARK stainless steel filters are widely used in industrial cooling water treatment systems where durability, corrosion resistance, and reliable filtration are critical to maintaining continuous operation. These filters are ideal for both open-loop and closed-loop cooling systems and can be deployed at various points in the water circulation path.

- Cooling Tower Makeup Water: Pre-filtration of municipal or surface water before entry into open-loop cooling towers to prevent sediment buildup and scaling.

- Recirculating Loop Filtration: Removal of suspended solids, rust particles, and biological debris from closed-loop cooling systems to protect chillers, heat exchangers, and circulation pumps.

- Condenser and Chiller Protection: Inline installation before sensitive equipment to reduce fouling, improve heat transfer efficiency, and extend maintenance intervals.

- Process Water Polishing: Secondary filtration after sand filters or softeners to remove fine particles prior to critical process cooling applications.

- District Cooling and HVAC Plants: Integration into centralized or modular cooling systems for commercial buildings, industrial parks, or data centers.

- Chemical and Steel Plants: Deployment in high-demand industrial zones where water contamination risks and heat loads are substantial.

Whether your system handles brackish feedwater, softened makeup, or highly recycled cooling water, STARK stainless steel filters deliver robust, long-term performance with minimal intervention. They are also suitable for integration with automated flushing or monitoring systems.

STARK stainless steel filters are designed to meet the operational demands of modern cooling water systems in industrial facilities, HVAC plants, power stations, and chemical processing environments. These filters efficiently remove suspended solids, sand, rust particles, and biofouling materials from recirculating or makeup water, ensuring optimal system efficiency and extending equipment lifespan.

Constructed from high-grade stainless steel (SUS304, SUS316L, or duplex), the filter housing provides excellent corrosion resistance against chemically treated cooling water and varying pH levels. Interior surfaces are mechanically polished or electropolished to minimize scaling and fouling accumulation.

Filter Design Options

We offer multiple filtration formats to meet specific flow, pressure, and footprint constraints:

- Cartridge-Type Filter: Ideal for fine filtration (1–100 micron); easily replaceable elements; suitable for precision protection of heat exchangers or chillers.

- Basket-Type Filter: Designed for coarse filtration (100–800 micron); reusable stainless steel basket insert; optimized for high-flow cooling loops.

- Y-Strainer and Inline Filters: Compact solution for point-of-use protection or system branch lines; available with magnetic rods for metal particle removal.

Customizable Parameters

Each filter can be tailored to specific process conditions, including:

- Connection size and type (DN25–DN300; flanged, threaded, or clamped)

- Flow rate (from 5 m³/h to 200 m³/h)

- Working pressure (standard 1.0 MPa; optional up to 1.6 MPa)

- Housing material (SUS304 / SUS316L / Duplex / lined carbon steel)

- Element type (stainless steel mesh, pleated cartridges, or wedge wire)

Optional features include differential pressure gauges, automatic flushing ports, drain valves, and lifting lugs for large-diameter housings. Units can be integrated into skid-mounted cooling water treatment packages or supplied as standalone inline components.

Whether for central cooling towers or local process chillers, STARK stainless steel filters offer reliable, long-life protection with minimal maintenance and maximum adaptability.

| Parameter | Specification |

|---|---|

| Housing Material | SUS304 / SUS316L / Duplex Stainless Steel (optional lined steel) |

| Filter Element | Stainless steel mesh, pleated cartridge, wedge wire, or multi-bag type |

| Micron Rating | 1μm – 800μm (customizable by application) |

| Working Pressure | Up to 1.0 MPa (1.6 MPa available upon request) |

| Operating Temperature | 5°C to 120°C (dependent on gasket type) |

| Flow Rate Range | 5 m³/h – 200 m³/h per unit (scalable) |

| Connection Type | Flanged (DIN/ANSI), Threaded (BSP/NPT), or Sanitary Clamp |

| Installation Orientation | Vertical (standard), Horizontal (optional) |

| Standard Features | Drain valve, pressure gauge ports, lifting lugs |

| Optional Features | Auto-flushing port, DP sensor, magnetic trap, insulation layer |

| Compliance | GB/T, ISO 9001; welding and pressure test certificates available |

Note: Specifications are fully customizable. For large-volume cooling water projects or OEM system integration, please contact us for detailed drawings and flow selection support.

STARK stainless steel filters are widely used in industrial cooling water treatment systems where durability, corrosion resistance, and reliable filtration are critical to maintaining continuous operation. These filters are ideal for both open-loop and closed-loop cooling systems and can be deployed at various points in the water circulation path.

- Cooling Tower Makeup Water: Pre-filtration of municipal or surface water before entry into open-loop cooling towers to prevent sediment buildup and scaling.

- Recirculating Loop Filtration: Removal of suspended solids, rust particles, and biological debris from closed-loop cooling systems to protect chillers, heat exchangers, and circulation pumps.

- Condenser and Chiller Protection: Inline installation before sensitive equipment to reduce fouling, improve heat transfer efficiency, and extend maintenance intervals.

- Process Water Polishing: Secondary filtration after sand filters or softeners to remove fine particles prior to critical process cooling applications.

- District Cooling and HVAC Plants: Integration into centralized or modular cooling systems for commercial buildings, industrial parks, or data centers.

- Chemical and Steel Plants: Deployment in high-demand industrial zones where water contamination risks and heat loads are substantial.

Whether your system handles brackish feedwater, softened makeup, or highly recycled cooling water, STARK stainless steel filters deliver robust, long-term performance with minimal intervention. They are also suitable for integration with automated flushing or monitoring systems.