Premium FRP Composite Tank – Advanced Liquid Storage & Durability

Premium FRP Composite Tank – Advanced Liquid Storage & Durability

Our Premium FRP Composite Tank offers advanced liquid storage with exceptional durability and corrosion resistance. Featuring a sanitary HDPE liner and precision-wound fiberglass reinforcement, it is ideal for water treatment, chemical processing, and industrial applications.

Our Premium FRP Composite Tank offers advanced liquid storage with exceptional durability and corrosion resistance. Featuring a sanitary HDPE liner and precision-wound fiberglass reinforcement, it is ideal for water treatment, chemical processing, and industrial applications.

Premium FRP Composite Tank – Advanced Liquid Storage & Durability

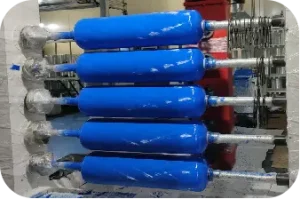

Product Overview

Our Premium FRP Composite Tank is engineered for advanced liquid storage across water treatment, chemical processing, and industrial applications. Constructed with a sanitary HDPE inner liner and reinforced by epoxy resin with precision-wound fiberglass, this tank offers superior durability, corrosion resistance, and long service life.

- Working Pressure: 125 PSI / 150 PSI

- Burst Pressure: ≥ 4x rated pressure

- Fatigue Tested: 100,000+ cycles

- Certifications: NSF, CE, ISO9001

- Available Sizes: 6" to 80" diameter (150mm–2000mm)

- Operating Temperature: 1°C – 49°C (34°F – 120°F)

Material Structure & Reinforcement

- Inner Liner: Made of sanitary-grade HDPE, blow-molded or rotomolded with integrated flange options for enhanced leak prevention.

- Winding Layer: Multi-axial CNC winding using epoxy resin and fiberglass for stable wall thickness and uniform strength.

- Curing Process: Thermal curing at 60°C for approximately 6 hours to enhance bonding and toughness.

Port Options

- Threaded Ports (2.5” / 4”): Constructed from reinforced PPO plastic with support ribs, compatible with standard NPT threads.

- Flanged Ports (4” / 6”): Embedded during liner molding for leak-proof integration, featuring 24 mounting holes per flange.

Manufacturing Equipment & Quality Control

- State-of-the-art CNC winding systems ensure precision and consistency.

- Final inspection includes pressure testing, dimensional checks, and thread verification.

Quality & Assembly Control

- Epoxy self-leveling workshop floors ensure precise tank-to-base alignment.

- Each tank is leveled and verified for assembly accuracy before packaging.

- Final inspection includes pressure testing and dimensional checks.

Product Parameter

| Specification | Detail |

|---|---|

| Working Pressure | 125 PSI / 150 PSI |

| Burst Pressure | ≥ 4x rated pressure |

| Fatigue Tested | 100,000+ cycles |

| Certifications | NSF, CE, ISO9001 |

| Available Sizes | 6" to 80" diameter (150mm–2000mm) |

| Operating Temperature | 1°C – 49°C (34°F – 120°F) |

Applicable Industry

Our Premium FRP Composite Tank is widely utilized in industries demanding robust, corrosion-resistant liquid storage solutions:

- Water Treatment Systems: Pre-treatment, softening, filtration, and RO system buffer tanks.

- Chemical Dosing Systems: Safe storage of acids, alkalis, coagulants, and disinfectants.

- Industrial Process Water: Intermediate storage for clean or recycled process fluids.

- Food & Beverage Plants: Raw water, CIP solution tanks, and water reuse storage.

- Power Plants: Demineralized water, cooling tower makeup, or sludge storage.

- Municipal Projects: Groundwater storage, booster tank systems, and rural supply solutions.

Premium FRP Composite Tank – Advanced Liquid Storage & Durability

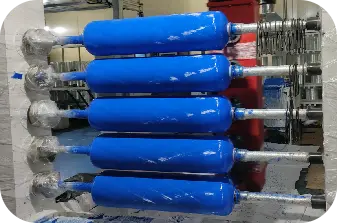

Product Overview

Our Premium FRP Composite Tank is engineered for advanced liquid storage across water treatment, chemical processing, and industrial applications. Constructed with a sanitary HDPE inner liner and reinforced by epoxy resin with precision-wound fiberglass, this tank offers superior durability, corrosion resistance, and long service life.

- Working Pressure: 125 PSI / 150 PSI

- Burst Pressure: ≥ 4x rated pressure

- Fatigue Tested: 100,000+ cycles

- Certifications: NSF, CE, ISO9001

- Available Sizes: 6" to 80" diameter (150mm–2000mm)

- Operating Temperature: 1°C – 49°C (34°F – 120°F)

Material Structure & Reinforcement

- Inner Liner: Made of sanitary-grade HDPE, blow-molded or rotomolded with integrated flange options for enhanced leak prevention.

- Winding Layer: Multi-axial CNC winding using epoxy resin and fiberglass for stable wall thickness and uniform strength.

- Curing Process: Thermal curing at 60°C for approximately 6 hours to enhance bonding and toughness.

Port Options

- Threaded Ports (2.5” / 4”): Constructed from reinforced PPO plastic with support ribs, compatible with standard NPT threads.

- Flanged Ports (4” / 6”): Embedded during liner molding for leak-proof integration, featuring 24 mounting holes per flange.

Manufacturing Equipment & Quality Control

- State-of-the-art CNC winding systems ensure precision and consistency.

- Final inspection includes pressure testing, dimensional checks, and thread verification.

Quality & Assembly Control

- Epoxy self-leveling workshop floors ensure precise tank-to-base alignment.

- Each tank is leveled and verified for assembly accuracy before packaging.

- Final inspection includes pressure testing and dimensional checks.

Product Parameter

| Specification | Detail |

|---|---|

| Working Pressure | 125 PSI / 150 PSI |

| Burst Pressure | ≥ 4x rated pressure |

| Fatigue Tested | 100,000+ cycles |

| Certifications | NSF, CE, ISO9001 |

| Available Sizes | 6" to 80" diameter (150mm–2000mm) |

| Operating Temperature | 1°C – 49°C (34°F – 120°F) |

Applicable Industry

Our Premium FRP Composite Tank is widely utilized in industries demanding robust, corrosion-resistant liquid storage solutions:

- Water Treatment Systems: Pre-treatment, softening, filtration, and RO system buffer tanks.

- Chemical Dosing Systems: Safe storage of acids, alkalis, coagulants, and disinfectants.

- Industrial Process Water: Intermediate storage for clean or recycled process fluids.

- Food & Beverage Plants: Raw water, CIP solution tanks, and water reuse storage.

- Power Plants: Demineralized water, cooling tower makeup, or sludge storage.

- Municipal Projects: Groundwater storage, booster tank systems, and rural supply solutions.