10000L Horizontal Stainless Steel Water Tank – STARK

10000L Horizontal Stainless Steel Water Tank – STARK

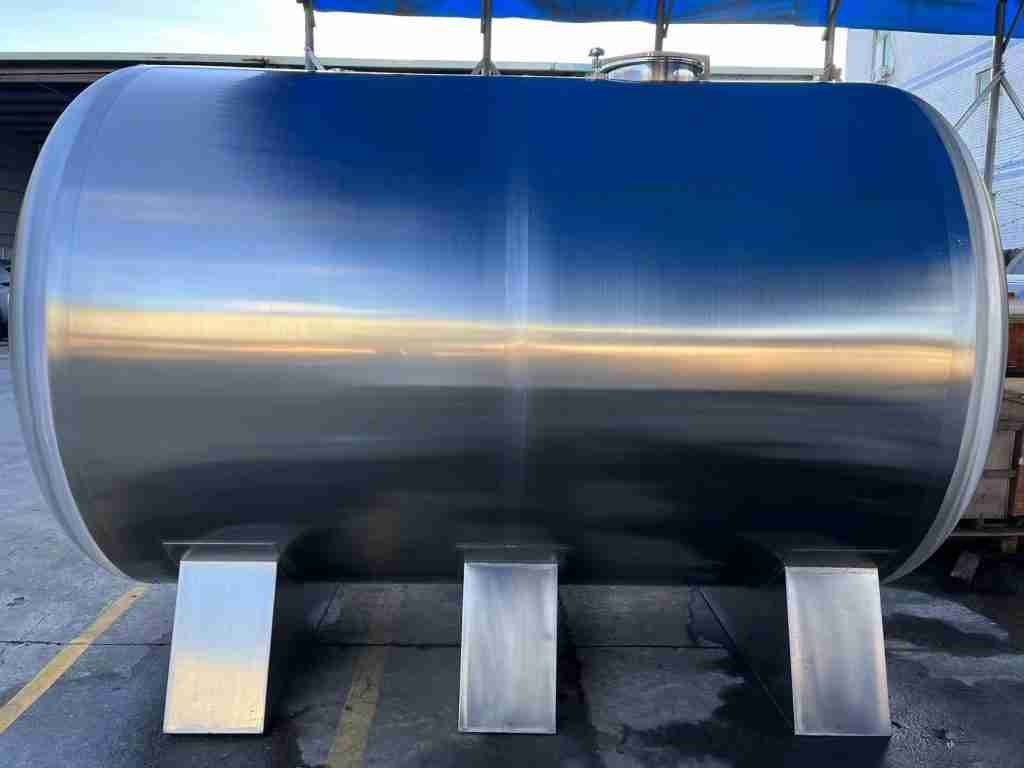

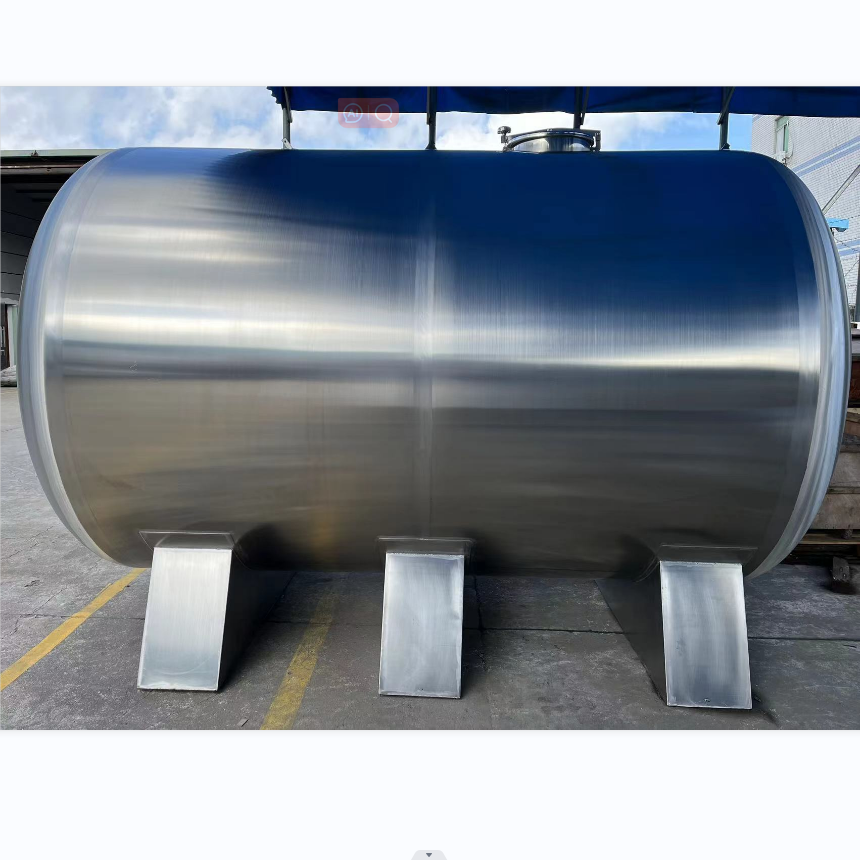

STARK's 10000L horizontal stainless steel water tank is designed for high-volume liquid storage in industrial and agricultural environments. Its ground-mounted cylindrical design offers enhanced stability and safety for static installation or mobile transport applications.

Built from corrosion-resistant SUS304 or SUS316 stainless steel, this tank is suitable for storing potable water, process water, or other non-reactive liquids. Customization is available for outlet ports, support saddles, inspection manholes, and pressure accessories.

STARK's 10000L horizontal stainless steel water tank is designed for high-volume liquid storage in industrial and agricultural environments. Its ground-mounted cylindrical design offers enhanced stability and safety for static installation or mobile transport applications.

Built from corrosion-resistant SUS304 or SUS316 stainless steel, this tank is suitable for storing potable water, process water, or other non-reactive liquids. Customization is available for outlet ports, support saddles, inspection manholes, and pressure accessories.

The STARK 10000L Horizontal Stainless Steel Water Tank is a purpose-built storage vessel optimized for bulk water and process liquid management. Its horizontal orientation provides excellent load distribution and is ideal for ground-level or mobile applications where low height and enhanced lateral stability are preferred over traditional vertical designs.

Constructed with TIG-welded SUS304 or SUS316 stainless steel, the tank features a cylindrical shell reinforced with anti-deformation ring ribs, mounted on two or more robust saddle supports. These supports are precisely calculated based on the tank's total filled weight, ensuring long-term structural integrity on concrete pads or trailer platforms.

Compared to vertical tanks, this 10000L horizontal configuration significantly reduces the overall installation height, which is critical for indoor plantrooms, transport trailers, or rooftop platforms. The design also enhances seismic safety by lowering the center of gravity and reducing wind-load surface area. Optional anchoring flanges and seismic restraint kits can be added for high-risk zones.

Each tank supports multiple inlet/outlet connections, typically ranging from DN50 to DN100, using tri-clamp, flanged, or threaded ends. Optional slope-bottom discharges, CIP spray ball nozzles, and large manhole openings (DN400–DN600) make internal cleaning and liquid drainage highly efficient. When thermal control is needed, we offer polyurethane insulation, rock wool jackets, and full-length stainless steel outer cladding.

Automation-ready features include level sensor ports (4–20mA or digital), float switches, temperature probes, and PLC-compatible sight glass integration. For mobile water treatment skids or trailer installations, lifting lugs, anti-slip walkways, and anti-roll stabilizers can also be incorporated into the tank frame.

This tank is especially suited for agricultural irrigation reserves, remote RO station storage, municipal emergency supply, stormwater buffering, and greywater reuse systems. Its high-volume capacity (10000L) allows single-tank redundancy in decentralized treatment sites, reducing maintenance frequency and operator workload.

As with all STARK tanks, engineering-grade support is provided, including CAD layout drawings, structural load calculations, and optional documentation packages such as CE marking, ISO 9001 traceability, and GMP compliance. Fully customized fabrication is available for specific dimensional constraints, pressure-holding needs, or regional code requirements.

| Parameter | Value | Description |

|---|---|---|

| Tank Capacity | 10000 Liters / 10 m³ | Effective working volume, customizable |

| Orientation | Horizontal Cylindrical | Low center of gravity, stable on ground or trailer |

| Material Options | SUS304 / SUS316L | Choose based on chemical resistance & hygiene |

| Wall Thickness | 2.0 – 4.0 mm | Depending on pressure, insulation, or transport use |

| Outer Dimensions | Φ1600 × 5200 mm (approx.) | Customizable diameter and length |

| Support Type | Fixed/Adjustable Saddle Stands | Reinforced stainless steel cradles with anchoring holes |

| Inlet/Outlet Ports | DN50–DN100 (Tri-clamp / Flange) | Position and size fully customizable |

| Drainage Configuration | Slope Bottom with DN65 Discharge | Efficient full-drain system, optional ball valve |

| Surface Finish | Mirror-polished (Ra ≤ 0.6μm inside) | Hygienic and easy to clean |

| Thermal Insulation | Optional PU / Rock Wool Jacket | Stainless steel outer cladding (0.5–1.0 mm) |

| Access & Cleaning | DN400–600 Manhole, CIP Spray Port | Top-mounted for manual or automated cleaning |

| Lifting & Handling | Top-mounted Lifting Lugs (4 points) | Supports hoisting & trailer mounting |

| Certification (Optional) | CE / ISO 9001 / GMP | Traceability documents & drawings available |

The STARK 10000L Horizontal Stainless Steel Water Tank is engineered to perform in high-demand, real-world environments where safe, stable, and hygienic water storage is critical. Its modular construction, corrosion-resistant material, and customization flexibility make it ideal for over 10 core industries across infrastructure, agriculture, industrial processing, and environmental sustainability.

- Water Treatment & Purification Systems:

Installed as raw water holding tanks or permeate reservoirs in RO, UF, or EDI systems. Horizontal tanks are often chosen in containerized systems or trailer-mounted skids where vertical space is limited. CIP-ready ports and slope bottoms make cleaning and maintenance efficient. - Agricultural Irrigation & Fertilizer Mixing:

Widely used in greenhouses, orchards, and crop fields to store irrigation water or pre-mixed nutrients. Horizontal tanks can be ground-mounted or buried partially for insulation. Stainless steel construction resists mineral scaling and corrosion from fertilizer compounds. - Rainwater Harvesting & Greywater Reuse:

Acts as a long-term reservoir in eco-friendly residential or commercial buildings. The low-profile shape allows it to be installed under walkways or decks. Optional filtration and overflow modules support closed-loop systems. - Municipal Emergency Preparedness:

Stockpiled as static or mobile tanks for earthquake, flood, or wildfire response. Easily deployable with forklift slots and lifting lugs. Stainless steel ensures clean water availability for weeks without bacterial growth or leaching. - Food & Beverage Manufacturing:

Used in dairy, beverage, and brewery operations to store ingredient water, pre-blend solutions, or cleaning water. SUS316 models handle acidic and low-pH media like fruit juice or brine. Optional manholes, insulation jackets, and mixing paddles available for batch processing. - Construction & Mining Sites:

Deployed as mobile water tanks for dust suppression, worker consumption, or concrete mixing. Saddle-mounted tanks can be truck-integrated or site-mounted with minimal foundation requirements. Heavy-duty versions available with shock-resistant ribs and bottom drains. - Livestock, Poultry & Aquaculture:

Installed as drinking water buffers or cleaning fluid tanks in animal production. Resistant to biofilm buildup and easy to disinfect. Float switches and float valves enable auto-refill cycles based on demand. - Cosmetics & Personal Care Production:

Used as utility water tanks, rinse tanks, or ingredient buffer tanks for shampoo, lotion, or fragrance dilution. Horizontal tanks are often integrated into space-constrained modular cleanroom environments and support sanitary-grade configurations. - Industrial Process Cooling & Wastewater Recovery:

Functions as chilled water return buffer, coolant overflow tank, or pre-treatment water reservoir. Insulated versions reduce energy loss. Dual-compartment or baffle-type designs available for separating inflow/outflow chambers. - Fire Protection Water Storage:

Maintains a dedicated emergency water reserve for fire suppression systems in factories, airports, and warehouse districts. Horizontal tanks are compatible with diesel-driven or electric booster pumps and comply with NFPA recommendations for auxiliary tanks. - Mobile Humanitarian & NGO Operations:

Utilized by non-profits and emergency service agencies to deliver or store drinking water in refugee camps, rural outreach stations, or disaster zones. Tanks can be laser-etched with fill-level indicators and come with tamper-proof inlets for water security.

The STARK 10000L Horizontal Stainless Steel Water Tank is a purpose-built storage vessel optimized for bulk water and process liquid management. Its horizontal orientation provides excellent load distribution and is ideal for ground-level or mobile applications where low height and enhanced lateral stability are preferred over traditional vertical designs.

Constructed with TIG-welded SUS304 or SUS316 stainless steel, the tank features a cylindrical shell reinforced with anti-deformation ring ribs, mounted on two or more robust saddle supports. These supports are precisely calculated based on the tank's total filled weight, ensuring long-term structural integrity on concrete pads or trailer platforms.

Compared to vertical tanks, this 10000L horizontal configuration significantly reduces the overall installation height, which is critical for indoor plantrooms, transport trailers, or rooftop platforms. The design also enhances seismic safety by lowering the center of gravity and reducing wind-load surface area. Optional anchoring flanges and seismic restraint kits can be added for high-risk zones.

Each tank supports multiple inlet/outlet connections, typically ranging from DN50 to DN100, using tri-clamp, flanged, or threaded ends. Optional slope-bottom discharges, CIP spray ball nozzles, and large manhole openings (DN400–DN600) make internal cleaning and liquid drainage highly efficient. When thermal control is needed, we offer polyurethane insulation, rock wool jackets, and full-length stainless steel outer cladding.

Automation-ready features include level sensor ports (4–20mA or digital), float switches, temperature probes, and PLC-compatible sight glass integration. For mobile water treatment skids or trailer installations, lifting lugs, anti-slip walkways, and anti-roll stabilizers can also be incorporated into the tank frame.

This tank is especially suited for agricultural irrigation reserves, remote RO station storage, municipal emergency supply, stormwater buffering, and greywater reuse systems. Its high-volume capacity (10000L) allows single-tank redundancy in decentralized treatment sites, reducing maintenance frequency and operator workload.

As with all STARK tanks, engineering-grade support is provided, including CAD layout drawings, structural load calculations, and optional documentation packages such as CE marking, ISO 9001 traceability, and GMP compliance. Fully customized fabrication is available for specific dimensional constraints, pressure-holding needs, or regional code requirements.

| Parameter | Value | Description |

|---|---|---|

| Tank Capacity | 10000 Liters / 10 m³ | Effective working volume, customizable |

| Orientation | Horizontal Cylindrical | Low center of gravity, stable on ground or trailer |

| Material Options | SUS304 / SUS316L | Choose based on chemical resistance & hygiene |

| Wall Thickness | 2.0 – 4.0 mm | Depending on pressure, insulation, or transport use |

| Outer Dimensions | Φ1600 × 5200 mm (approx.) | Customizable diameter and length |

| Support Type | Fixed/Adjustable Saddle Stands | Reinforced stainless steel cradles with anchoring holes |

| Inlet/Outlet Ports | DN50–DN100 (Tri-clamp / Flange) | Position and size fully customizable |

| Drainage Configuration | Slope Bottom with DN65 Discharge | Efficient full-drain system, optional ball valve |

| Surface Finish | Mirror-polished (Ra ≤ 0.6μm inside) | Hygienic and easy to clean |

| Thermal Insulation | Optional PU / Rock Wool Jacket | Stainless steel outer cladding (0.5–1.0 mm) |

| Access & Cleaning | DN400–600 Manhole, CIP Spray Port | Top-mounted for manual or automated cleaning |

| Lifting & Handling | Top-mounted Lifting Lugs (4 points) | Supports hoisting & trailer mounting |

| Certification (Optional) | CE / ISO 9001 / GMP | Traceability documents & drawings available |

The STARK 10000L Horizontal Stainless Steel Water Tank is engineered to perform in high-demand, real-world environments where safe, stable, and hygienic water storage is critical. Its modular construction, corrosion-resistant material, and customization flexibility make it ideal for over 10 core industries across infrastructure, agriculture, industrial processing, and environmental sustainability.

- Water Treatment & Purification Systems:

Installed as raw water holding tanks or permeate reservoirs in RO, UF, or EDI systems. Horizontal tanks are often chosen in containerized systems or trailer-mounted skids where vertical space is limited. CIP-ready ports and slope bottoms make cleaning and maintenance efficient. - Agricultural Irrigation & Fertilizer Mixing:

Widely used in greenhouses, orchards, and crop fields to store irrigation water or pre-mixed nutrients. Horizontal tanks can be ground-mounted or buried partially for insulation. Stainless steel construction resists mineral scaling and corrosion from fertilizer compounds. - Rainwater Harvesting & Greywater Reuse:

Acts as a long-term reservoir in eco-friendly residential or commercial buildings. The low-profile shape allows it to be installed under walkways or decks. Optional filtration and overflow modules support closed-loop systems. - Municipal Emergency Preparedness:

Stockpiled as static or mobile tanks for earthquake, flood, or wildfire response. Easily deployable with forklift slots and lifting lugs. Stainless steel ensures clean water availability for weeks without bacterial growth or leaching. - Food & Beverage Manufacturing:

Used in dairy, beverage, and brewery operations to store ingredient water, pre-blend solutions, or cleaning water. SUS316 models handle acidic and low-pH media like fruit juice or brine. Optional manholes, insulation jackets, and mixing paddles available for batch processing. - Construction & Mining Sites:

Deployed as mobile water tanks for dust suppression, worker consumption, or concrete mixing. Saddle-mounted tanks can be truck-integrated or site-mounted with minimal foundation requirements. Heavy-duty versions available with shock-resistant ribs and bottom drains. - Livestock, Poultry & Aquaculture:

Installed as drinking water buffers or cleaning fluid tanks in animal production. Resistant to biofilm buildup and easy to disinfect. Float switches and float valves enable auto-refill cycles based on demand. - Cosmetics & Personal Care Production:

Used as utility water tanks, rinse tanks, or ingredient buffer tanks for shampoo, lotion, or fragrance dilution. Horizontal tanks are often integrated into space-constrained modular cleanroom environments and support sanitary-grade configurations. - Industrial Process Cooling & Wastewater Recovery:

Functions as chilled water return buffer, coolant overflow tank, or pre-treatment water reservoir. Insulated versions reduce energy loss. Dual-compartment or baffle-type designs available for separating inflow/outflow chambers. - Fire Protection Water Storage:

Maintains a dedicated emergency water reserve for fire suppression systems in factories, airports, and warehouse districts. Horizontal tanks are compatible with diesel-driven or electric booster pumps and comply with NFPA recommendations for auxiliary tanks. - Mobile Humanitarian & NGO Operations:

Utilized by non-profits and emergency service agencies to deliver or store drinking water in refugee camps, rural outreach stations, or disaster zones. Tanks can be laser-etched with fill-level indicators and come with tamper-proof inlets for water security.